Fan Coil Units

Fan coil unit (FCU) is a simple device consisting of a heating or cooling coil and fan. It is part of an HVAC system found in residential, commercial and industrial buildings. A fan coil unit can be used with or without ductwork and is used to control the temperature in the space where it is installed or serve multiple spaces. It is controlled either by a manual on/ off switch or by thermostat.

Features & Other Accessories

Fan Coil Units

Features

- Compact Design

- Easy access for service

- SS Drain Pan included

- AHRI 410 Certified Coil performance

- Elegant Tripod Water Inlet / Outlet

- Permanent Split Capacitor Motor/ EC Motor Slent, Low noise levels.

- 3 Rows / 4 Rows Cooling / Heating Coils

- 2 Pipe / 4 Pipe Systems

- Equiped with Nano Filter Media filters

- Energy saving range of fans

Other Accessories

- 2 Way Valve

- Hydrophilic coated cooling coils

- Copper Fins

- Thermostat

- PICVValve

- Anti corrosive Coating

- Electric Heater

- BLDC Motor

- EC fans

Technical Specifications

Fan Coil Units

| Model | ZFCU – 04 | ZFCU – 06 | ZFCU – 08 | ZFCU – 10 | ZFCU – 12 | ZFCU – 16 | ZFCU – 18 | |

| CFM / TR | 400 / 1.0 | 600 / 1.5 | 800 / 2.0 | 1000 / 2.5 | 1200 / 3.0 | 1600 / 4.0 | 1800 / 4.25 | |

| COILS | Connections | 3/4″ | ||||||

| Air Vent | Manual and Furnished on All Coils | |||||||

| Fin Material | Plain Aluminum / Blue Coated Hydrophilic | |||||||

| Fin Spacing, FPI | 12 | |||||||

| Tube Material | Copper | |||||||

| Test Pressure | 350 psig | |||||||

| Maximum Working Pressure | 200 psig | |||||||

| FANS | Diameter X Width, (Inch) | 6.5X7 | 6.5X7 | 6.5X8 | 8X8 | 8X8 | 7X7 | 7X7 |

| Number Per Unit | 2 | 2 | 2 | 2 | 2 | 4 | 4 | |

| Construction | Aluminium- Dynamically Balanced | |||||||

| MOTORS | Watt (hp) | 37 (1/20) | 37 (1/20) | 37 (1/20) | 93 (1/8) | 93 (1/8) | 186 (1/4) | 186 (1/4) |

| (PSC) | Quantity | 1 | 2 | |||||

| MOTORS | Watt | 60 | 60 | 60 | 130 | 130 | – | – |

| (BLDC) | Quantity | 1 | – | |||||

| Sound Pressure (dB) | 40 / 42 / 44 | 44 / 45 / 46 | 45 / 46 / 47 | 46 / 47 / 48 | 47 / 48 / 49 | 49 / 51 / 53 | 49 / 51 / 53 | |

| (Low / Med / High) | ||||||||

| Unit Weight, kg | 23 | 26 | 29 | 42 | 44 | 52 | 52 | |

How it Works

Fan Coil Units

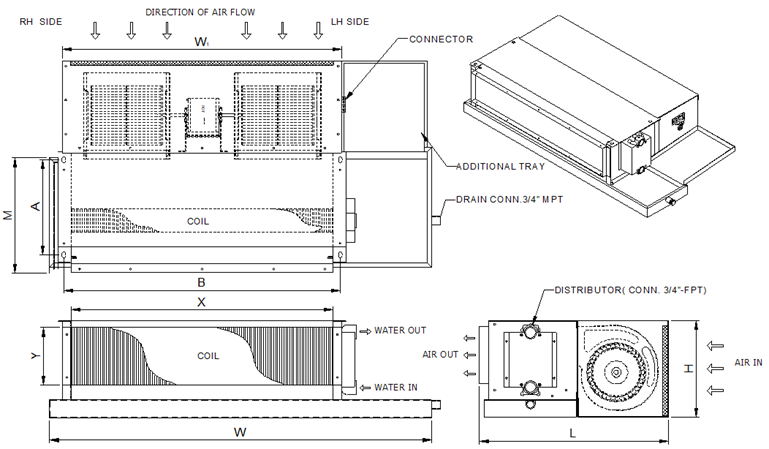

Standard Cooling Application

CFM RANGE 1 TR - 4.5 TR

| MODEL | L | W | H | A | B | DUCT CONN. |

| (X x Y) | ||||||

| 1 TR | 520 | 1066 | 270 | 200 | 772 | 730 X 160 |

| 1.5 TR | 520 | 1182 | 270 | 200 | 892 | 846 X 160 |

| 2 TR | 530 | 1232 | 320 | 205 | 938 | 896 X 210 |

| 2.5 TR | 685 | 1420 | 370 | 265 | 1082 | 1040 X 210 |

| 3 TR | 685 | 1420 | 370 | 265 | 1082 | 1040 X 260 |

| 4 TR | 570 | 1785 | 330 | 205 | 1500 | 1420 X 230 |

| 4.5 TR | 570 | 1785 | 370 | 205 | 1500 | 1420 X 230 |

District Cooling Application

CFM RANGE 1 TR - 4 TR

| MODEL | L | W | H | A | B | DUCT CONN. |

| (X x Y) | ||||||

| 1 TR | 520 | 1098 | 270 | 200 | 804 | 762 X 160 |

| 1.5 TR | 530 | 1382 | 270 | 200 | 1092 | 1046 X 160 |

| 2 TR | 530 | 1331 | 370 | 205 | 1037 | 995 X 260 |

| 2.5 TR | 685 | 1765 | 370 | 265 | 1427 | 1385 X 260 |

| ZFCU-12 | 685 | 1904 | 370 | 265 | 1566 | 1524 X 260 |

Fan Coil Unit (FCU)

Our FCU consists of a blow-through/draw-through arrangement of a fan and coil. Our AHRI-tested and certified FCU offers a customizable compact; range for 0.5TR to 5TR and a high static pressure range. A fan coil unit can be with or without ductwork and is used to control the temperature in spaces like residencies, hotels, commercial buildings or offices.

Certified by

Technical Specifications

| FCU Details | ||||||||

| S.No. | Parameters | Technical Data Sheet | ||||||

| 1 | Air Flow (CFM) | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 |

| 2 | ESP (Pa) | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| 3 | Speed | Medium | Medium | Medium | Medium | Medium | Medium | Medium |

| 4 | Filter Thickness | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| 5 | Filter Media | Metallic | Metallic | Metallic | Metallic | Metallic | Metallic | Metallic |

| 6 | Filter Efficiency | EU4 | EU4 | EU4 | EU4 | EU4 | EU4 | EU4 |

| 7 | Copper Tube Dia. (IN.) | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 | 3/8 |

| 8 | Fin Material | Al | Al | Al | Al | Al | Al | Al |

| 9 | Total Capacity (TR) | 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 4 |

| 10 | Sensible Capacity (TR) | 0.39 | 0.75 | 1.2 | 1.5 | 1.85 | 2.2 | 2.95 |

| 11 | Coil RD | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| 12 | Fin Spacing (FPI) | 12 | 12 | 12 | 12 | 12 | 12 | 12 |

| 13 | Entering Water Temp | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 | 6.5 |

| 14 | Leaving Water Temp | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 | 12.5 |

| 15 | Air Entering Temp. (DB) | 24.5 | 24.5 | 24.5 | 24.5 | 24.5 | 24.5 | 24.5 |

| 16 | Air Entering Rh (%) | 51.6 | 51.6 | 51.6 | 51.6 | 51.6 | 51.6 | 51.6 |

| 17 | Air Leaving Temp. (DB) | 15.6 | 13.7 | 13.7 | 13 | 13 | 12.7 | 12.9 |

| 18 | Air Leaving RH (%) | 80.1 | 85.5 | 85.5 | 87.2 | 87.4 | 88 | 87.5 |

| 19 | Face Velocity (MPS) | 0.19 | 0.48 | 0.71 | 1.02 | 1.29 | 1.59 | 2.07 |

Optional Accessories

- 2 Way Valve

- Hydrophilic Coated Cooling Coils

- Copper Fins

- Thermostat

- PICV Valve

- Anti Corrosive Coating

- Electric Heater

- BLDC Motor

- EC fans

| Cooling Capacity (TR) | Dimension Data | ||

| Length (mm) | Width (mm) | Height (mm) | |

| 0.5 TR | 520 | 806 | 270 |

| 1.0 TR | 520 | 1066 | 270 |

| 1.5 TR | 520 | 1182 | 270 |

| 2.0 TR | 530 | 1232 | 320 |

| 2.5 TR | 685 | 1420 | 370 |

| 3.0 TR | 685 | 1420 | 370 |

| 4.0 TR | 570 | 1785 | 330 |

Features & Benefits

- Compact design

- Easy access for service

- SS drain pan included

- AHRI 410 certified coil performance

- Elegant tripod water Inlet / Outlet

- Permanent Split Capacitor Motor / EC

- Low noise levels

- 3 Rows / 4 Rows cooling / Heating coils

- 2 Pipe / 4 Pipe systems

- Equipped with Nano Media filters

- Energy saving range of fans

Applications

- Commercial Buildings

- Residential Buildings

- Hotels

- Restaurants